|

|||||||||||||||||||||||||||||||||||||||||||||

|

<< Introduction >>

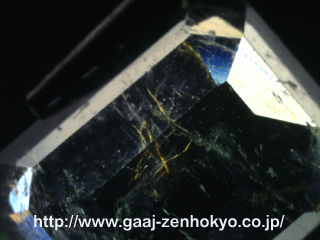

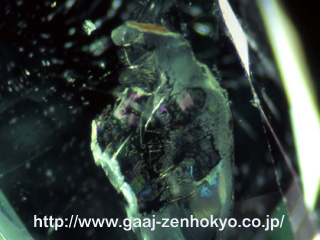

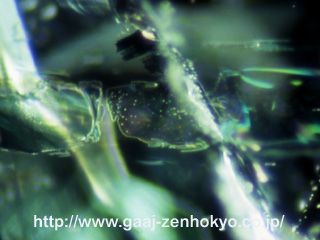

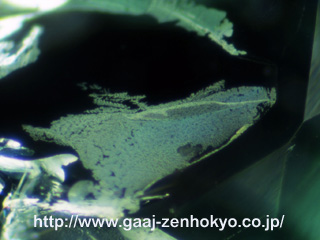

As it is often said that "no flawless emerald exists", emerald from any locality generally contains inclusions. Many crystals have already fractures at the time of mining and these fractures are potentially enlarged by careless handling during cutting, polishing or processing into jewellery. To make those surface-reaching flaws less obvious emeralds have been traditionally filled with transparent substance since long time ago. As you know from your experience that an ice loses its relief when put in clear water, a fissure in emerald becomes less visible when it is filled with a substance that has close RI to that of emerald. RI of emerald is around 1.57〜1.59 and a substance to be filled is oil or resin that has similar RI values. Various types of filling material are known and the most widely used are cedarwood oil and paraffin oil. Cedarwood oil is extracted from several kinds of coniferous tree but mainly from juniper. Other material contains epoxy resin that had become widely used rapidly since late1980s. Resin has closer RI to emerald than oil and it is more effective to improve apparent clarity (transparency). The Opticon, well known in the industry, is a commercial name and it is one type of epoxy resin. << Detection of Filling Material >> Characteristic features observed in magnification test Important information on filling in emerald can be obtained by combining magnification test using a gemmological microscope with various illumination techniques. 1.Flash Effect Flash effect is often observed in filled fissures. This is caused by difference in dispersion between emerald and filled material although they have similar RIs. For example, dispersion colour was blue to violet when observing a filled fissure against light background (= in bright field illumination) (photo 1), but it changes to orange when observing obliquely against dark background (= in dark field illumination) (photo 2). The combination of colour change can be reversed in different cases. Epoxy resins such as Opticon has closer RIs to that of emerald than oil, therefore stones filled with those resins typically show this flash effect (photo 3 and 4). The flash effect is distinctly observed in dark field illumination when combined with a fibre optic light source.

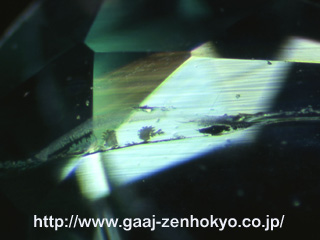

2.Gas bubbles and Residues Filled fissure often contains gas bubbles inside. Untreated emeralds may also show gas bubbles in included two-phase (i.e., gas contained in fluid that fills a cavity) or three-phase (i.e., solid and gas contained in fluid that fills a cavity) inclusions, and such gas appear as spheres with low relief while gas seen in filling material is often platy (photo 5) with high relief (photo 6). The gas seen in oil filling is in smaller size and occurs less frequently (photo 7 and 8), while that in resin filling is in irregular shape with various sizes. If a fissure is perfectly filled with a substance the fissure practically disappears, however, when the filled material changes in quality (such as emulsifying or oxidation), the material becomes visible as a distinct residual substance. White substance is observed in resin but more often it is observed in fissures filled with oil (photo 9). A fissure filled with oil may often appear brownish in bright field illumination due to oxidation (photo 10) and the residue may characteristically appear dendritic (photo 11).

|

|||||||||||||||||||||||||||||||||||||||||||||

|