|

||||||||||||||||||||||||||||||||||||||||

| We recently encountered synthetic rubies that seemed to be difficult to identify with standard gemmological tests. After our analysis, these rubies were proved as heat-treated RamauraTM-type flux-grown synthetic rubies. The background and their gemmological features are introduced here. With the enforcement of amendments to the regulation of description on identification reports last September, AGL (Association of Gemmological Laboratories Japan) determined that comment on heat treatment in corundum should be stated individually. Before that, detection of heated or non-heated corundum was not made but only a comment ‘corundum is commonly applied to enhancement’ was indicated as a memo on the identification report. The new amendments, therefore, require more tasks to laboratory members of AGL. Observation of detailed internal features becomes important to identify heat-treated corundum. Many crystal inclusions have lower melting points than corundum and they will dissolve or discolour by heating, while liquid inclusions will adhere by heating and catalyst used for heating process may be seen in fractures as residue. Heating process will change spectrum in UV-visible region and infrared region. Blue sapphires heated in reducing atmosphere will show absorption caused by OH, which is not seen before heating. Similarly, heat-treated rubies from Mong Hsu district show absorption due to OH that bonded structurally. In this manner, heating and non-heating in corundum can be detected by standard identification techniques (including spectrometry such as FTIR) defined by AGL, however, there will be a case in which overall judgement using more sophisticated analytical methods such as X-ray fluorescence analysis, Raman spectroscopic analysis or laser tomography is required. Laser tomography is especially useful to determine heating/non-heating because it can sensitively detect development of dislocation or change in fluorescence colour due to heating. Back to the subject, heat treatment is applied not only to natural corundum but also to synthetic stones. For instance, certain type of synthetic ruby is basically difficult to identify and, more over, its internal features change after heat treatment thus its identification becomes more complicated. At the beginning of 1990s, many heat-treated Verneuil synthetic rubies were sent to gem market while natural rubies from Vietnam appeared on the market. The Verneuil synthetic rubies had been traditionally easy to identify under magnification test with their characteristic curved lines, however, heat treatment induced feathers with liquid-like appearance in the stone and this made the material much more difficult to identify. In the middle of 1990s, heated Kashan synthetic rubies appeared on the market. These were quite large (2ct to 27ct) crystals and considerable amount have presumably be distributed domestically (see GEMMOLOGY 1996, Nov). Synthetic rubies that show features of RamauraTM ruby have been heated recently, and this is raising a new problem in ruby identification. RamauraTM ruby is a flux-grown synthetic stone that has been on sale since 1983. At the beginning of the sale, the manufacturer allegedly added rare-earth elements during its synthesis intending to give an indication of its origin because the material was difficult to distinguish from natural ruby. We found this year that some of these RamauraTM ruby were heat-treated and became more difficult to identify. According to the first client who brought this type of ruby, he obtained the piece in Bangkok as a natural ruby from Myanmar. Other clients also bought same type of stones in Bangkok so that we presume that some people obtain rough or faceted RamauraTM rubies somehow and heat them in Thailand. Our laboratory has tested so far less than ten pieces of rough ranging from 0.5 to 1ct (photo 1) and a 2.5ct piece set on a ring.

The properties of these rubies such as RI, DR and SG are totally overlapping on those of natural ruby and give no identification clue. The material shows bright red colour in UV fluorescence test under both LWUV and SWUV, however, the intensity of fluorescence is not strong enough to indicate its synthetic origin. Orange flux appearing as dissolved into several substances was observed (photo 2, 3 and 4),

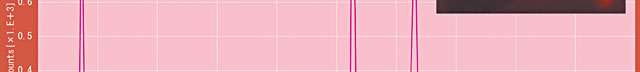

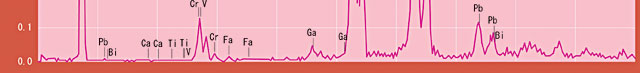

which was characteristic to the flux that was mainly composed of lead to be used for RamauraTM ruby and DourosTM ruby. But its characteristic orange colour is difficult to observe under dark-field illumination as it is masked by bright red body colour, and a strong fibre optic light is required for observation. The surface reaching flux was analysed by fluorescent X-ray, which can measure minute area, and, as shown in fig 1, lead (Pb) and bismuth (Bi) in a ratio of 3 to 1 were detected.

This is a typical feature to RamauraTM ruby but not to DourosTM ruby. Chemical composition of whole pieces were similarly analysed, and considerable amount of chromium (Cr) as well as trace elements such as iron (Fe), calcium (Ca) and gallium (Ga) were detected other than the main component aluminium (Al). Iron content constrains the strength of UV fluorescence, and the existence of gallium is generally a characteristic feature to natural ruby, while trace elements commonly seen in natural ruby such as titanium (Ti) and vanadium (V) were under detection limit. This indicates that identification with compositional analysis also requires sufficient analytical ability for a gemmologist. Under magnification test, feather inclusion (photo 5, 6), minute inclusion (photo 7), uneven colour distribution (photo 8) and growth lines (photo 9), all of which are quite similar to those of a natural ruby, will be observed and the identification should be made with the greatest care.

|

||||||||||||||||||||||||||||||||||||||||