Rubies that have been improved their clarity by lead glass filling are rapidly widespread recently. Many of permeated fractures of these rubies do not show flash effect that once had been uniquely seen in permeated material. This type of treatment now is also seen in jewellery with a star ruby or a necklace with beads. Details of the treatment are introduced here.

As it was reported on the May 2004 issue of this magazine, a new treatment on ruby to improve its clarity by filled lead glass that has RI close to ruby started to appear on the market. The new treatment spread out rapidly after December 2004, and many cases of serious condition have been reported from overseas as well as domestically.

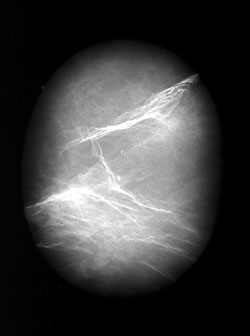

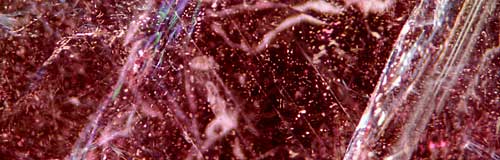

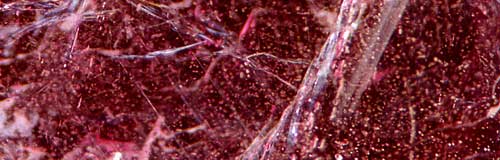

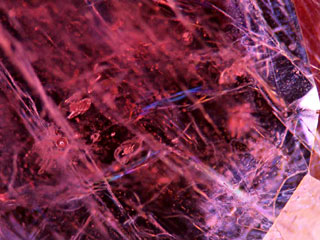

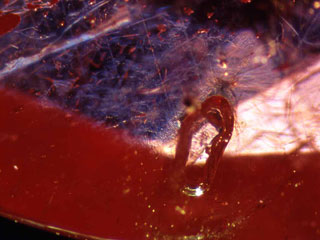

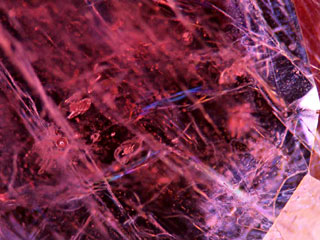

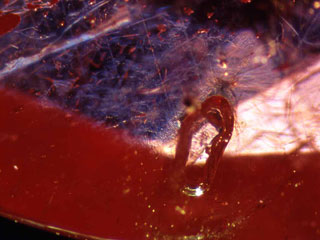

The filling treatment that has been already reported shows flash effect (blue to purple unnatural light-effect that is different from ordinary interference of thin film) in a faceted ruby (photo 1). Also observed is a gas bubble trapped planate in a filled fracture (photo 2 and 3).

|

|

| Photo.1:filling treatment showing flash effect |

Photo.2:planate gas bubble trapped in a fracture |

|

|

| Photo.3:large gas bubble trapped in a fracture |

Residues from heating process are often seen in cavities or fractures of a ruby, however, they have far lower RI than ruby and therefore no flash-effect is seen. Flash effect indicates filling on ruby with a substance that has close RI to ruby. By an X-ray fluorescence analysis, Pb (lead) was detected from a surface-reaching fracture, and by LA-ICP-MS analysis, B (boron) in thousands ppm order was detected.

Recently, a new type of filling treatment, which shows no flash effect, is dramatically increasing. Shown in a photo 4 are star rubies treated with lead glass filling. Faceted rubies that previously reported have all been heated to improve their colour. On the other hand, these star rubies show no evidence of heating under high temperature aiming at improvement of colour or asterism. They also show no flash effect on their fracture, but a few gas bubbles left as planate indicate the filling treatment (photo 5).

|

|

| Photo.4: |

star rubies with filling treatment

(4.888ct, 3.720ct) |

|

Photo.5:fracture that shows no flash effect |

This type of filling on star rubies has been increased recently, but GAAJ had confirmed the treatment in May 1997 and the treatment process itself was not a new technique.

Shown in the photo 6 is a necklace of ruby beads. Each ruby is in the size of about 4×3 mm, almost all of which showed an indication of filling treatment. Photo 7 shows the observation of reflected light from them, in which surface-reaching fractures appear slightly less reflective. Radiographs of these stones are shown in the photo 8. Many white streaks in high relief correspond to fractures developed in rubies. Uniformly white part indicates that existence of elements that have greater mass than the host ruby (Al2O3), and elemental analysis revealed that the part coincides with filled lead glass.

|

|

| Photo.6: |

a necklace of bead with filling treatment |

|

| Photo.7: |

observation of reflected light; filled part shows lower relief |

|

|

|

| Photo.8: |

a radiograph; streaks in high relief correspond to filled fracture. |

|

Traditional type of filling treatment that produces flash effect on a stone was proved to use lead glass with high purity by analyses with X-ray fluorescence and LA-ICP-MS, while the recent filled material with no flash effect (with slightly lower RI) is a lead glass containing Si and Ca of about several percents and Na, K, B and Li of thousands ppm.

Filling treatment on ruby with lead glass for clarity improvement has been widely seen since last year. Among these stones, the treated stones with no flash effect may pose difficulty to its identification visually. In such a case, the stone should be confirmed with a radiograph or X-ray fluorescence analyses. |