|

||||||||||||||||||||||||||||||||||||

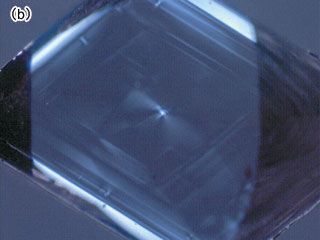

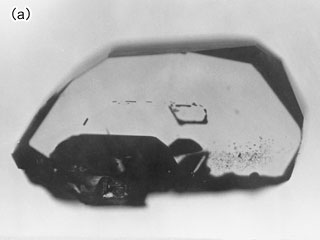

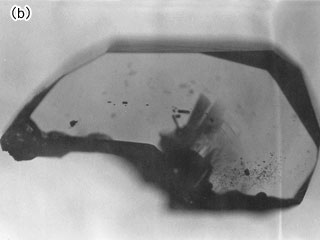

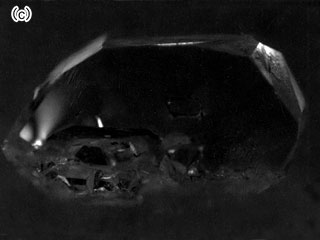

| 1. Introduction Several years have passed since a heat treatment technique with high temperature and high pressure (HPHT treatment) to lighten colour of natural brown diamond crystal became a topic, but there are still many unknown points in the process. To understand fully the problem of HPHT treatment, it is important to study history of natural diamonds, especially how brown stones are formed, as well as to understand each alteration caused during the HPHT treatment on diamonds. In this report we focus on the formation process of natural brown diamonds. A big difference between natural brown diamond and colourless transparent diamond, other than their colours, is strain inside crystals, which can be clearly observed by a polarizing microscope as shown in fig 1. Streaky pattern due to strain is prominently seen in brown crystal. From this fact, brown diamonds are presumed to produce strain in its crystal structure by receiving anisotropic force after the growth under the ground. This stain probably cause some defect in the crystal and thus it becomes the cause of the brown colour. We performed experiments to confirm this anticipation by creating strain artificially in diamond and observed its change. We operated HPHT treatment, which usually aims to remove strain but in this experiment it was made to aim to produce strain. It is the most desirable to confirm that brown colouration appears when strain is produced in a crystal, however there are some limitations in its experiment method and we this time observed influence of strain by using cathode luminescence (CL). The result showed that the cathode luminescence characteristically seen in brown diamonds was also seen in the diamonds in which strain has been artificially induced.

Å@Å@A sample used for the experiment was originally a single crystal, 2mm in diameter polyhedron, of typeII synthesised by high pressure, which was polished tabular. The crystal with various parts including a heater were built into a sample composition shown in fig.-2, and set in a extra-high-pressure device called belt-type, which usually is used to synthesise diamond (the photo is shown in fig.-3).

Cathode luminescence (CL) is the light emitted from a substance when illuminated by electron beam, and it is used for Braun tube in the TV set. In Brown tube, electrons hit fluorescer coated on a screen to generate light, which our eyes perceive. The CL is highly sensitive to impurity in a substance and it can detect minute amount of impurity even fewer than parts per million. The colour of luminescence also indicates a type of impurity contained. A photograph of the CL device used for this study is shown in fig.-5. This is a scanning-type electron microscope set with a spectrometer (an instrument to measure wavelength of light), and its diagram is shown in fig.-4. A sample generates light when hit by electron from electron gun. The light is converged by concaved mirror to be introduced to the spectrometer, in which diffraction gratings divide the light into each wavelength. They are then sent to a detector and transformed into electronic signal to show a graph of luminescence spectrum, which we can see as the measured data.

3. Result 3.1 Photo against Transmitted Light Shown in fig.-6 is the crystal before and after the heat treatment. Photos were taken against transmitted light, and one pair of them was taken through a polarising sheet. The crystal is colourless transparent, and the colour has not changed after the heat treatment, although some influences of heat treatment under extra-high-pressure such as partial destruction or deformed inclusion were recognised. The difference of the crystal before and after the heat treatment becomes more obvious when observed under a polarised light. The crystal does not transmit the polarised light and appears dark before the treatment whereas it shows patchy pattern after the treatment due to strain produced in the crystal structure.

|

||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||